Coal Tar Pitch Roofing Details

Historically coal tar pitch was used as a component on the first sealed roads has served as a heating element and was used to manufacture paints synthetic dyes and photographic materials.

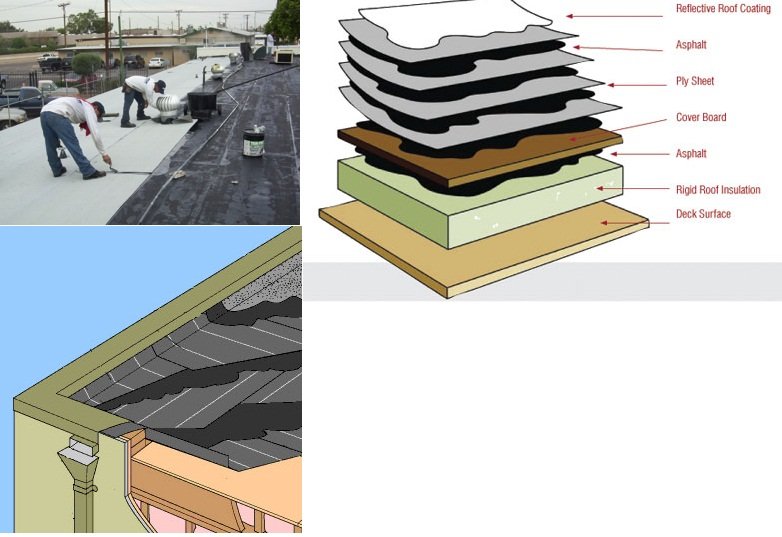

Coal tar pitch roofing details. It is solid for all practical purposes at room temperature. Astm d450 standard specification for coal tar pitch used in roofing dampproofing and waterproofing covers the testing and physical requirements of two types of coal tar pitch. Coal tar pitch was a by product of processing coal to make coke which in turn was used in making carbon steel and electrodes for the aluminum industry. The traditional black armor coal tar built up roof remains an important part of this business and our industry.

Type ii which has a lower softening point 106 to 126. Coal tar pitch is produced by distilling or heat treating coal tar which is a by product of the production of coke or coal gas. Construction definition coal tar pitch roofing. Built up roofing in which coal tar pitch forms the waterproofing component of the roof membrane.

History of coal tar roof systems. The traditional coal tar built up roof is one of the most reliable and longest lasting low slope commercial flat roofing systems available. However honeywell s millennium a coal tar based polymer modified membrane system is gaining popularity and is revitalizing the market s interest in coal tar systems. A coal tar roofing system represents the industry s premier built up roof membrane assembly.

Coal tar pitch is an excellent waterproofing agent described as self healing because it readily flows to seal breaks in waterproofing and roof membranes. Coal tar pitch is derived from coal distillation and should not be confused with roofing asphalt which is a product of crude oil refining. The same self healing characteristic restricts the use of coal tar pitch to roof systems of little or no slope typically 1 8 of an inch per foot or less. Bituminous roofing hits the market back in the pre world war ii years there were two bituminous substances bitumens that dominated the roofing industry.

A waterproofing material used since the beginning of time coal tar pitch is a superior and sustainable raw material that is ideal for use within a roofing membrane system. Coal tar s unique molecular structure provides a system that resists water and vapor penetration insect damage chemical attack uv exposure and most elements considered common enemies to other roof membrane systems. Type i which is generally used in roofing and dampproofing.