439 Stainless Steel Vs 316

Figure 4 cyclic oxidation ak steel 439 ultra form stainless steel 1500 f 816 c.

439 stainless steel vs 316. These two types of stainless steel are categorized by their microstructure. Three benefits of using 316 stainless steel 1. Due to the addition of molybdenum grade 316 stainless steel is more corrosion resistant than similar alloys such as 304 stainless steel. When it comes to applications with chlorinated solutions or exposure to salt grade 316 stainless steel is considered superior.

Stainless 316 contains more nickel than stainless 304 while 304 contains more chromium than 316. This grade may be used in the annealed cold formed or as welded condition in applications where other stainless steels such as type 304 304l and type 430 are used. Other elements are added and the chromium content increased to improve the corrosion resistance and heat resisting properties enhance mechanical properties and or improve fabricating characteristics. There are over 50 stainless steel grades that were.

316l is an austenitic stainless steel and 439 is a ferritic stainless steel. The stainless panels will be cleanable will require no painting and the grade form ability machin ability weld ability 303 1 8 1 304 8 5 8 316 8 5 8 444 6 5 5 416 1. 409 stainless steel will rust on the surface. Most modern factory exhaust systems are made from 409 stainless steel.

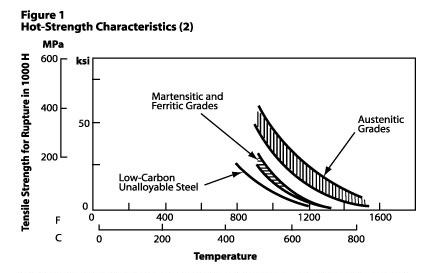

Type 439 is an 18 chromium titanium stabilized ferritic stainless steel with corrosion resistance similar to that of 304 304l stainless steel. The ak steel 439 ultra form stainless steel samples at 1700 f 926 c gained 320 mg in 2 after 1000 cycles but were not determined as catastrophic failures. 201 201ln 301 304 304l 316 316l 409 410 430 439 441 just as there is a range of structural and engineering carbon steels ref. Ak steel 11 cr cb stainless steel and aluminized type 409 data are shown for comparison.

Molybdenum is a chemical element used for the strengthening and hardening of steel. Stainless steel is more likely to crack due to this internal stress. However this is not a concern for most people because it is hidden under the vehicle. Stainless steel is not a single alloy but rather the name applies to a group of iron based alloys containing a minimum of 10 5 chromium.

Stainless 304 usually consists of 18 chromium and 8 nickel. Olympic steel meeting different requirements of strength weldability and hardness so is there a wide range of stainless steels with progressively higher levels of strength and corrosion. This designation is related to the microstructure of the metal the differences can be seen under an electron microscope in this picture a is austenitic 304 and b is ferritic 430.